The versatile 304L stainless steel is now more in demand than ever, for it plays a vital role in construction and food processing while also being sought after in the automotive industry. As with any industrial material, the manufacturers strive to deliver the best quality using advanced technology and engineering, and stainless steel producers are no exception. The exceptional properties of 304L steel, such as damage-tolerant flexibility and superior corrosion resistance, have made it predestined and zinc-plated in industries all over the world. These manufacturers don’t just produce stainless steel; they pave the way for infrastructural benchmarks.

Coming to focus are companies that have impeccably manufactured stainless steel coils. From this list, Zheijiang Zhongzheng Stainless Steel Manufacturing Co., Ltd. is an industry leader known for its innovative approach to rising global standards. With advanced facilities, they can provide high-quality coils that promptly fit customers’ requirements. Alongside them is Galaxy Metal Product Wuxi Co., Ltd., whose unwavering focus on environmental conservation alongside their unique production techniques earns them trust as an international supplier.

The stainless steel industry’s chaotic and robust competitive landscape is as dynamic as the industry itself. Adaptability to market shifts and a commitment to quality and customer loyalty distinguish these unrivaled sterling manufacturers from others. Allow me to take you into the depths of these unrivaled sterling manufacturers and two other extraordinary manufacturers to uncover what makes them acclaimed suppliers of 304L stainless steel coils.

Don’t worry if you belong to an industry that depends on these coils or are simply intrigued by these manufacturers and what characteristics help them stand out. Join me as I unravel the undiscovered domain of stainless steel coils, innovation, rigor, and expertise that help these manufacturers achieve distinction amongst their peers and determine success in craftsmanship.

What Makes a 304L Stainless Steel Coil Factory Stand Out?

- High-Quality Materials: Responsible factories use appropriate raw materials while constructing their 304L stainless steel coils, which are inexpensive and have the required durability and corrosion resistance.

- Modern Manufacturing Processes: Effective production techniques and advanced technology guarantee the precision, homogeneity, and quality of the products at every step of manufacturing.

- Certified Standards Compliance: Primary providers maintain international requirements like ISO certifications to validate the authenticity of their products.

- Systematic and rigorous allocation tests and verification methods ensure thorough examination and validation of the product’s integrity prior to its distribution.

- Strong Industry Reputation: Dependable Factories are always known to have a good reputation due to their use of 3D printers, good track record, and customer comments.

How to Choose the Right 304L Stainless Steel Coil Supplier?

Choosing the best 304L stainless steel coil supplier is critical to preserve reliability, quality, and cost-effectiveness. We shall discuss some of the factors that you should keep in mind while making a decision:

- Material Certification and Standards

Check if the supplier’s quality protocols include ISO 9001, ASTM compliance, or other international standards and coils. This ensures industrial needs will be met.

- Product Range and Customization Options

A dependable supplier will have to fulfill all requested specifications of 304L stainless steel coils regarding thickness, width, surface finishing, and other customization options.

- Competitive Pricing with Transparency

Compare all relevant suppliers to ensure value for money. Pricing details should also be clearly laid out without undisclosed or unexplained add-ons.

- Delivery Capabilities and Lead Time

Make sure the supplier meets the requested timelines and checks their delivery schedule. On-time material delivery requires an efficient logistical framework to maintain supply chain fluidity.

- Technical Support and After-Sales Service

The best technical support will come from those who understand the materials well. Thus, make sure relevant experts are part of your suppliers. The expectations of relevant experts have to be met; otherwise, prompt issue resolution will not be possible.

Discovering the Best Top 4 304L Stainless Steel Coil Factories for Your Needs

When it comes to purchasing 304L stainless steel coils, consider these industry leaders with claims on superb customer service and quality: Zhejiang Zhongzheng Stainless Steel Manufacturing Co., Galaxy Metal Product Wuxi Co., TW Metals, and Xinjing Stainless Steel. Their precision and accuracy in the field of stainless steel, alongside their profound product quality and customer service, make them known worldwide.

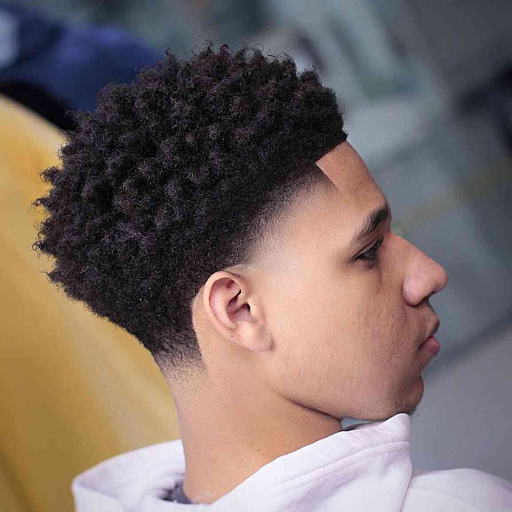

1. Zhejiang Zhongzheng Stainless Steel Manufacturing Co., Ltd.

Zhejiang Zhongzheng Stainless Steel Manufacturing Co., Ltd. specializes in stainless steel manufacturing as a prominent producer of 304L steel coils. Located in China’s Zhejiang region, the firm is reputed for having state-of-the-art manufacturing plants and a rigid quality control system. Their 304L stainless steel coils are corrosion-resistant, exceptionally durable, and compliant with international standards, rendering them suitable for construction, automotive, and chemical applications. The company’s relentless innovation and customer focus have propelled its rapid growth. By employing advanced technology and a stern focus on customers, Zhejiang Zhongzheng has become a dependable name globally.

2. Galaxy Metal Product Wuxi Co., Ltd.

Galaxy Metal Product Wuxi Co., Ltd. is well known for producing a wide range of stainless steel products, which include 304L stainless steel coils. The company is located in Wuxi, China, with modern production facilities and skilled employees. Their 304L coils have gained fame for superb corrosion resistance and precision and versatility for food processing, transportation, and petrochemical industries. Galaxy Metals has developed a positive worldwide reputation due to its quality assurance, competitive prices, punctual delivery, and planned shipment of goods. Their devotion toward innovation and sustaining the environment has made them a market leader.

3. TW Metals

TW Metals operates in the United States and is a world-renowned supplier of high-quality stainless steel products for industries like aerospace. TW Metals is well known for their wide inventory and various processing options. They also serve pharmaceuticals and architecture. The company also sells 304L stainless steel coils that meet AMS5511 and ASTM A240 certifications, giving excellence and reliability. World-renowned TW Metals became a preferred choice for many clients due to their customer service and accuracy in custom orders. Their sustained growth resulted from a strong focus on innovation and efficiency.

4. Xinjing Stainless Steel

Xinjing Stainless Steel has an established reputation as a manufacturer of stainless steel coils and other products, including the 304L variant. Over the past twenty years, this company has consistently provided high-quality products that serve the broad scope of industrial requirements. The 304L coils of stainless steel are particularly famous for possessing outstanding mechanical strength, corrosion resistance, and versatility for many applications. Expansion into global markets has been aided by Xinjing’s high-quality production techniques, customer satisfaction, and dedicated marketing strategies. Innovation and controlling costs have also played heavily into their business successes.

What are the Applications of 304L Stainless Steel Coils?

The corrosion resistance, strength, and versatility offered by 304L Stainless Steel make it easy to see its widespread usage in the following industries:

- Chemical Processing—This includes their use in storage tanks, piping systems, and fabrication equipment used in chemical production.

- Food and Beverage Industry – Used in manufacturing kitchen appliances, storage containers, and various processing machinery.

- Construction – Architectural panels as well as corrosion-resistant roofing and structural elements.

- Medical Equipment – For non reactive and hygienic properties, used in surgical devices, implants and available hospital equipment.

- Automotive – It is used in exhaust systems as well as in areas prone to high temperatures and corrosion.

These examples provide a foundation on which we can claim the resiliency of 304L Stainless Steel Coils against demanding environments.

Common Uses in Stainless Steel Sheet Production

| Industry | Common Uses |

| Construction | Cladding, roofing, structural supports |

| Foodservice | Kitchen counters, food processing equipment |

| Medical | Surgical instruments, hospital furniture |

| Automotive | Exhaust systems, trims, body panels |

| Aerospace | Engine components, structural parts |

| Marine | Boat fittings, propellers, deck hardware |

| Consumer Goods | Appliances, cookware, decorative finishes |

Advantages in Weld and Fabrication Projects

Due to its advantages, 304L stainless steel is a valuable material for weld and fabrication applications. One of its unique features is its low carbon content. This significantly reduces the chances of carbide precipitation during welding, making oxygen-resistant materials even more durable. For that reason, the material can be used for long-term application projects.

Another advantage of using 304L stainless steel is its outstanding formability. Shape retention helps maintain structures within necessary complex designs but does not compromise strength. This property becomes incredibly useful in precise fabrication-related work within specialized industries like food processing, aerospace, and construction.

Recent studies indicate that 304L has a tensile strength of approximately 70,000 PSI (pounds per square inch) and a yield strength of 25,000 PSI, suggesting that it is durable yet flexible for countless welding applications. In addition, it can withstand -150°F to anything over 1400°F; therefore, it can operate under extreme temperatures, providing great adaptability for various environments.

Another fabrication-friendly advantage of 304L stainless steel is that it can be welded using numerous techniques, such as TIG and MIG, as well as manual arc welding. Such versatility reduces fabrication effort, equipment, or specialized techniques needed to complete the project. Further, its superior oxidation resistance ensures the longevity of structures subjected to high temperatures or corrosive elements.

In industries where cost is essential, 304L stainless steel is inexpensive compared to other high-performance alloys, making it a versatile, economical choice for sectors dealing with fabrication or weld projects.

What Are the Differences Between 304 and 304L Stainless Steel?

| Parameter | 304 Stainless Steel | 304L Stainless Steel |

| Carbon Content | Max 0.08% | Max 0.03% |

| Tensile Strength | 620 MPa (90 ksi) | 586 MPa (85 ksi) |

| Yield Strength | 289 MPa (42 ksi) | 241 MPa (35 ksi) |

| Corrosion Resistance | Lower at weld joints | Higher at weld joints |

| Welding Suitability | Requires annealing after welding | No annealing needed |

| Applications | General-purpose | Corrosive/welded environments |

Comparing Corrosion Resistance and Durability

While comparing 304 and 304L stainless steels, we can see how both differ concerning corrosion resistance and even durability. Here are five in-depth points that set apart the two alloys:

- Carbon Content

304 Stainless Steel Has greater carbon levels, up to 0.08%, which might react with high temperatures, causing carbide precipitation, which can decrease corrosion resistance for some environments.

304L Stainless Steel: The “L” signifies this grade has a low carbon level (maximum 0.03%), which helps to minimize carbide precipitation, thus improving corrosion resistance when welding or using it at high temperatures.

- Intergranular Corrosion Resistance

304 Stainless Steel: Has lower resistance to intergranular corrosion due to exposure at 800-1500 (427-815 degrees C) because of the higher carbon level.

304L Stainless Steel maintains the same range of intergranular corrosion but is more resistant in that temperature range, making it suitable for welding and heat-affected applications.

- Weldability

304 Stainless Steel: Need to take steps to avoid sensitization and subsequent corrosion in the weld joins.

304L Stainless Steel: Better weldability due to low carbon content. Most parts do not require post-weld annealing which decreases production time and cost.

- Strength and Hardness

304 Stainless Steel: Provides greater tensile strength and hardness relative to 304L, which is beneficial in areas with higher strength.

304L Stainless Steel: Relatively weaker and softer in comparison, it is more adaptable to weld environments and has improved corrosion resistance.

- Applications

304 Stainless Steel: Used for parts that are mechanical in nature which require higher strength but have minimal welding or exposure to harsh environments like corrosive fluid, as well architectural aids.

304L Stainless Steel: Commonly used in naval construction for chemical processing and other industries where welding sustains damage, but protection against corrosion is essential.

These differences allow the selection of materials in 304 and 304L stainless steel to be tailored as needed based on usage requirements in terms of strength and resistance to corrosion while ease of fabrication.

Deciding Between 304 Stainless Steel and 304L for Your Projects

I start with their application specifications in my decision-making regarding 304 stainless steel and 304L. For projects involving welding or with an increased risk of intergranular corrosion, 304L is preferred due to its minimal carbon content and superior resistance. If the project involves moderate welding and general-grade corrosion, standard 304 stainless steel is ideal due to its overall strength and more than adequate resistance properties. These factors have to be balanced at all times to guarantee optimal performance and longevity.

Frequently Asked Questions (FAQ)

Q: What are the main features of a 304L stainless steel coil?

A: A 304L stainless steel coil is known for its low carbon content, which enhances its corrosion resistance and makes it suitable for welding. It is a high-quality austenitic stainless steel with excellent mechanical properties and is commonly used in various applications, including rolling stainless steel coils.

Q: How do 304 and 304L stainless steel coils differ?

A: The primary difference between 304 and 304L stainless steel coils is the carbon content. 304L has a lower carbon content than 304, which reduces the risk of carbide precipitation during welding, making it ideal for use in environments where welding is required.

Q: What applications are suitable for cold-rolled stainless steel coils?

A: Cold-rolled stainless steel coils are used in applications that require precise dimensions and a superior surface finish. Due to their high-quality finish and excellent mechanical properties, they are commonly found in automotive parts, kitchen equipment, and architectural components.

Q: Why choose 201 stainless steel over other grades?

A: 201 stainless steel is a cost-effective alternative to other austenitic stainless steels like 304 and 316. It offers good formability and corrosion resistance, making it suitable for applications where cost is a consideration without compromising quality.

Q: What are the advantages of using hot-rolled stainless steel coils?

A: Hot-rolled stainless steel coils are known for their strength and durability. They are typically used in applications requiring structural integrity and are easier to work with in terms of bending and shaping than cold-rolled coils.

Q: How does the addition of alloying elements affect the properties of stainless steel coils?

A: Alloying elements such as chromium, nickel, and molybdenum enhance the corrosion resistance, strength, and toughness of stainless steel coils. These elements also influence the coil’s ability to withstand extreme temperatures and improve its mechanical properties.

Q: What should you consider when selecting a manufacturer and supplier for 304L stainless steel coils?

A: When selecting a manufacturer and supplier for 304L stainless steel coils, consider the supplier’s reputation, product quality, certifications, competitive pricing, and customer service. It’s also essential to ensure they can provide coils that meet your specific requirements and standards.

Q: What is the significance of AISI standards in stainless steel production?

A: AISI standards are crucial as they ensure the consistency and reliability of stainless steel products. These standards specify the chemical composition and mechanical properties required for different grades of stainless steel, ensuring that they meet industry requirements for quality and performance.

Q: How does the stainless steel coil price vary by grade and manufacturer?

A: The price of stainless steel coils can vary significantly based on the grade, with higher grades typically costing more due to their enhanced properties. Additionally, prices may vary between manufacturers based on factors such as production capabilities, market demand, and supply chain efficiencies.

Q: What role does a stainless steel mill play in producing high-quality coils?

A: A stainless steel mill is responsible for the initial production of stainless steel coils, ensuring they meet required specifications and standards. The mill’s capabilities in terms of technology, equipment, and expertise directly influence the quality of the final product, making it essential for creating high-quality stainless steel coils.